Idaho Falls: The First Nuclear Meltdown in America’s History

A Closer Look at the Importance of Nuclear Safety Training

The explosion at SL-1 U.S. Army research facility near Idaho Falls in 1961 during the early years of nuclear power development was a grim and tragic reminder of the power and danger of nuclear fission. The accident resulted from a range of factors, including inadequate design, inadequate materials testing, and poor procedures and training.

Idaho, 1961

In the frigid cold of an Idaho night, the fate of America's nuclear ambitions took a shocking turn. It was January 3rd, 1961, when the remote tranquillity of an isolated U.S. army nuclear research facility near Idaho Falls was shattered by a cataclysmic event that would challenge the growing confidence of America’s aspiration to control and harness the power of nuclear fission.

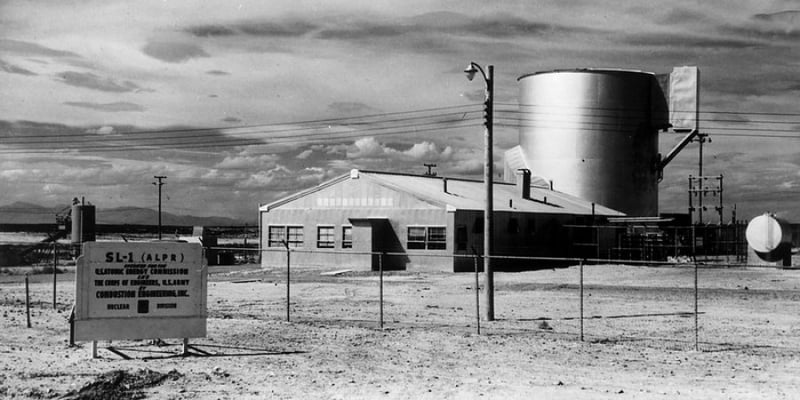

SL-1 Reactor

Located at this remote outpost was the U.S Army’s Stationary Low Power Reactor Number One, better known as SL-1. This was an experimental nuclear power reactor, whose future purpose was to revolutionise the ability to generate energy in remote locations. But behind the bold project of innovation lay a story of negligence, ambition, and tragedy.

While the U.S. Navy was developing nuclear power plants for a future fleet of submarines and the Air Force was bringing forward plans for a nuclear-powered bomber, the army programme, by comparison, was far less glamorous. The SL-1 purpose was to proof a design that would provide power for austere location signals and radar stations.

The more mundane although still important role of SL-1 was probably at the heart of an immature nuclear industry’s lapse in design and oversight of the project, which received neither the funding nor attention of other projects.

Nuclear Meltdown

On the night of January 3rd, SL-1 was being bought back to life after a long Christmas and New Year shutdown. Three men, army specialists Richard McKinley and John Burns, alongside Navy electrician Richard Legg, were responsible for this start up. These men didn’t have a significant amount of experience in this role, however, it had been argued that the whole purpose of SL-1 was low maintenance with small, military non-specialist crews.

Following the event many conspiracy theories abounded about the men, with their allegedly poor discipline and character flaws luridly examined. In truth, the fateful events of that night probably had more to do with design failure and inadequate training than the off-duty lives of these inexperienced service men.

The most important part of the restart process was lifting the central control rod manually a mere four inches to reconnect it to its drive mechanism. Burns prepared to lift the more than 80-central pound rod with his bare hands while his supervisor Legg stood with him at the top of the reactor. Nearby stood Mckinley. At 9.01 pm a reactor that was rated for 200 kilowatts of power generation spiked to 100 000 times that amount producing 20 gigawatts in just four milliseconds. In a minuscule moment much faster than the blink of an eye, SL-1 obliterated itself, going supercritical and claiming the lives of all three operators. The aftermath left no witnesses, only speculation and controversy.

Related: Chernobyl: Drawing a Line Under Disaster

Why Did This Explosion Happen?

The quest for simplistic operation meant the reactor design contained only five operational control rods with the central control rod possessing the power to shut down or start up the reactor independently.

This was not enough to exercise proper control of the reactor. To make matters worse, the tendency of the control rods in SL-1 to stick had become well known with the unorthodox remedial procedure advised to crews to be the use of a large wrench to free them.

In the operation performed by Burns the control rod was removed too far causing the reactor to go ‘prompt critical’.

Prompt Critical

Prompt critical neutrons are the neutrons released first in a fission event. In the case of SL-1 the release of prompt critical neutrons in a 100-trillionth of a second created a power surge of 10 million percent above normal operation and explosively vaporised the core of the reactor.

Cooling water was blasted upwards by this vaporised fuel and struck the top of the vessel with an extreme amount of momentum that was sufficient to lift the entire 26-thousand-pound apparatus over nine feet into the air, create 500 pounds per square inch of pressure which forced the plugs at the top of the reactor open and fire the control rods like missiles into the ceiling.

The entire reactor room was instantly filled with burning steam contaminated water and fragments of the radioactive core.

SL1 had just gone prompt critical.

The Response and Clean Up

Firefighters alerted by the remote alarms arrived to find the site apparently deserted but with their radiation monitors reading off the scale.

Emergency planning had never before accounted for an event like the SL-1 explosion: medical equipment and facilities were unprepared to handle radioactive bodies; there was a lack of burial procedures for radioactive corpses; shift disaster teams were unorganised; the first rescue workers on the scene did not have proper gloves to protect their hands from the radiation; and instruments were unable to read high radiation fields.

Nevertheless, with considerable bravery, a cautious search found the body of Burns and the still moaning figure of McKinley. The Navy electrician Legg was not discovered for some while, until his barely recognisable remains were found impaled gruesomely to the ceiling by one of the control rods.

McKinley would die a few minutes after discovery, Legg’s body would involve a complex recovery from an area heavily contaminated by radiation and would take nearly a week.

Most of the radiation released by the SL-1 explosion was fortunately contained inside the building. This containment allowed the General Electric Corporation to remove the reactor vessel and undertake a laborious clean-up of the contaminated buildings.

In May 1961, GE constructed a burial ground near the original reactor site in which they sealed 99,000 cubic feet of contaminated material underground. The bodies of McKinley, Burns and Leg were not returned to their families. Instead, they were placed in lead line caskets inside of metal vaults and covered with concrete for burial.

Investigation

The investigation that followed painted a grim picture of neglect and systemic failures.

The SL1 reactor was in a terrible state before it exploded, plagued by malfunctions and corrosion, and looked after by workers whose total experience could be measured in months.

The army’s plans for a remote miniaturised reactor capability died with SL-1. Questions such as to why a reactor would be designed so perilously close to criticality, why would procedures actually dictate the manual lifting of that rod and why was an inexperienced operator allowed to perform dangerous maintenance with so little supervision, would cause a fundamental reappraisal of reactor design.

The theories surrounding the cause of the explosion would abound. However, the practice in these early days of experimenting with nuclear power involving poor design, poor supervision, poor maintenance, and poor engineering, provide the most likely reasons for this disaster.

Related: Bringing Radiation Training to Life

Utilising Nuclear Safety Training to Avoid Disasters Like Idaho Falls

While nuclear safety training was in its infancy when the Idaho Falls disaster occurred, these days, the safe use of nuclear power is much more established. Coupled with better design and engineering, proper maintenance and safety procedures have been integral for avoiding further nuclear disasters like Idaho Falls.

Experienced personnel are also key for improved safety, and extensive training utilising devices such as survey meters (like the Ludlum Measurements Inc. RDS) and personal dosimeters (such as the UDR 13/14) has become crucial for any facility handling nuclear energy. As might be expected, however, any training that requires the use of radiation comes with significant risk and red tape.

This has led to the development of real experience training using modified devices which replicate every operational feature of a real detector. Rather than needing a real ionising radiation source, these devices respond to a harmless electronic signal which acts as a simulated source.

Utilising real experience training using simulators can be a massive game-changer for nuclear safety training in environments similar to that of Idaho Falls.

—--

In Idaho 1961, the American nuclear programme received a tragic reminder of the catastrophic consequences of getting nuclear science wrong. Moving forward with better safety precautions and improved training can help avoid future disasters.

To learn more about how simulators can be used during nuclear safety training, read our Introduction to Nuclear Training.

*Featured image: SL-1 looking North showing Reactor Building and tank with sign in foreground. Circa 1960, before the accident. Source: Flickr